- WOOD IS GOOD

- 07912 388993

- beamishpallets@icloud.com

Upcycling Wooden Pallets

Extend the life of your pallets.

March 28, 2019

Introducing the Cekamon Pallet stripping machine.

April 25, 2019Preparing Wooden Pallets for Upcycling Projects.

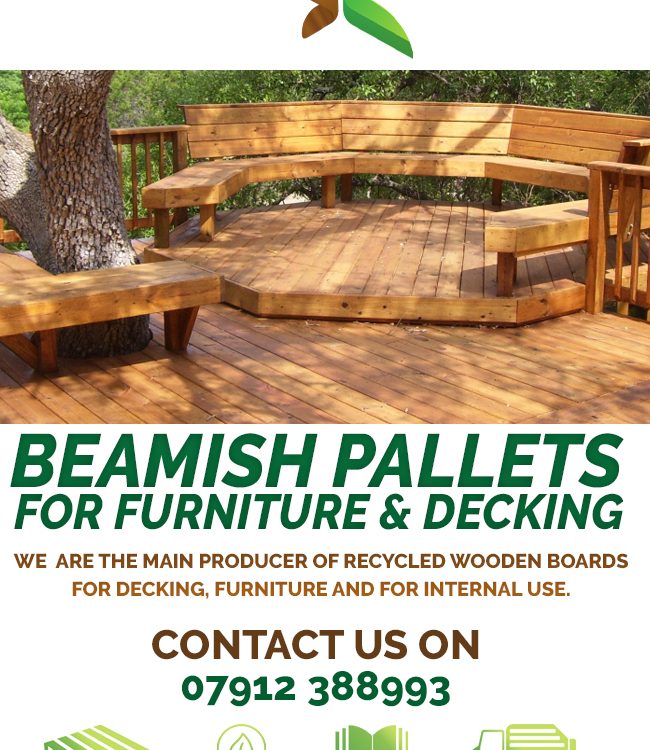

After being used as a basic wooden frame to load and transport goods via forklift, truck, and ship, the simple pallet can be transformed into numerous works of furniture art ranging from coffee tables, shelving, and picture frames to armoires, night stands, and bunk beds.

Most importantly you should come and get your pallet from us here at Beamish. As we can guarantee that our pallets will be free from toxic chemicals and in prime condition ready for sanding, priming & painting.

We would be happy to break down your pallet for you.

Great care should be taken when disassembling your pallets; after all, you don’t want to bust up your hard-earned discount wood! A few methods are less desirable than others to break down a pallet into its usable components so it’s a good idea to go over the basics. • Hammer, Pry Bar, and Cat’s Paw: A small cat’s paw or pry bar, a flat clawed hammer, and a block of wood are all you really need to break apart a pallet without damaging the surface of the wood. • Nail Punch: Using a nail punch to drive rather than pull the nails free can be the preferred method on stubborn ring, screw, or spiral-shanked nails. Pneumatic nail punches work even better, but can cost a pretty penny. • Oscillating Tool: By loosening up tight planks with a pry bar first, you can expose the nail shank to the cutting blade of an oscillating tool and make quick work of rusty nails. • Drill: When the above methods won’t work and you’re stuck with a nail that won’t budge, you can always use a metal drill bit and drill to remove ancient pallet nails. • Clean Cut: Last but not least (and if all else fails) you can quickly cut the pallet planks and leave the pallet ends and nails still attached to the stringer.

Cutting, Shaping, Sanding, and Finishing Tips

After all of the hard work of finding and breaking down your pallet pieces, you’ve still got to cut, shape, sand, and finish your materials before they are ready to be assembled into something new and fantastic. The easiest way to get your pallet projects started off on the right foot is by shaping, sanding, finishing, and cutting your materials prior to assembly. Because pallet materials are unfinished, they can be pretty rough – rough enough to cause a few painful splinters. But it’s also their rough nature that makes them so appealing, and sanding down to a smooth surface often takes away the aesthetic patina of a pallet’s natural state. If you’re going for the clean look of new wood, avoid lengthy sanding and go for a quick pass through a wood planer for clean, crisp, wood. However, if you like the tarnished veneer of your ancient pallet but want to make it smooth to the touch, use natural beeswax finishing products to highlight your pallet’s well-worn finish without keeping the sharp and dangerous splinters hanging around. When cutting and shaping pallet materials, it’s often wise to avoid making cuts near nail holes, splits, or cracks in the wood. As wood ages on pallets, it shrinks. This makes the wood more susceptible to splitting and breaking during a cut. Always be sure to sand your pallet materials in an outdoor setting and avoid breathing any dust by using a respirator. Dust and debris from sanding a pallet may contain traces of toxic materials from shipping spills, even if the pallet was never used to ship poisonous products. In lieu of sanding rough edges, a hand planer may be the best tool for the job to avoid creating potentially toxic dust. Pallet projects can range from creating an Adirondack chair to an outdoor garden bed. There are thousands of ways to upcycle a pallet into a piece of furniture or work of art. Creating an upcycled piece of art or furniture from a pallet is the perfect way to reuse wood that would otherwise be thrown away. Now that you have all the information about choosing the right pallet and preparing it for use, it is time to start your project.